This post is not really a blog, more a series of photos. Over the last month, I have been playing around with Autodesk Fusion 360 and getting some real experience with designing my own parts. Last week, I was finally pretty satisfied with my design for new base-plates and decided to get them laser cut in acrylic. Also, my old cardboard base-plate was bending due to the weight of the battery pack.

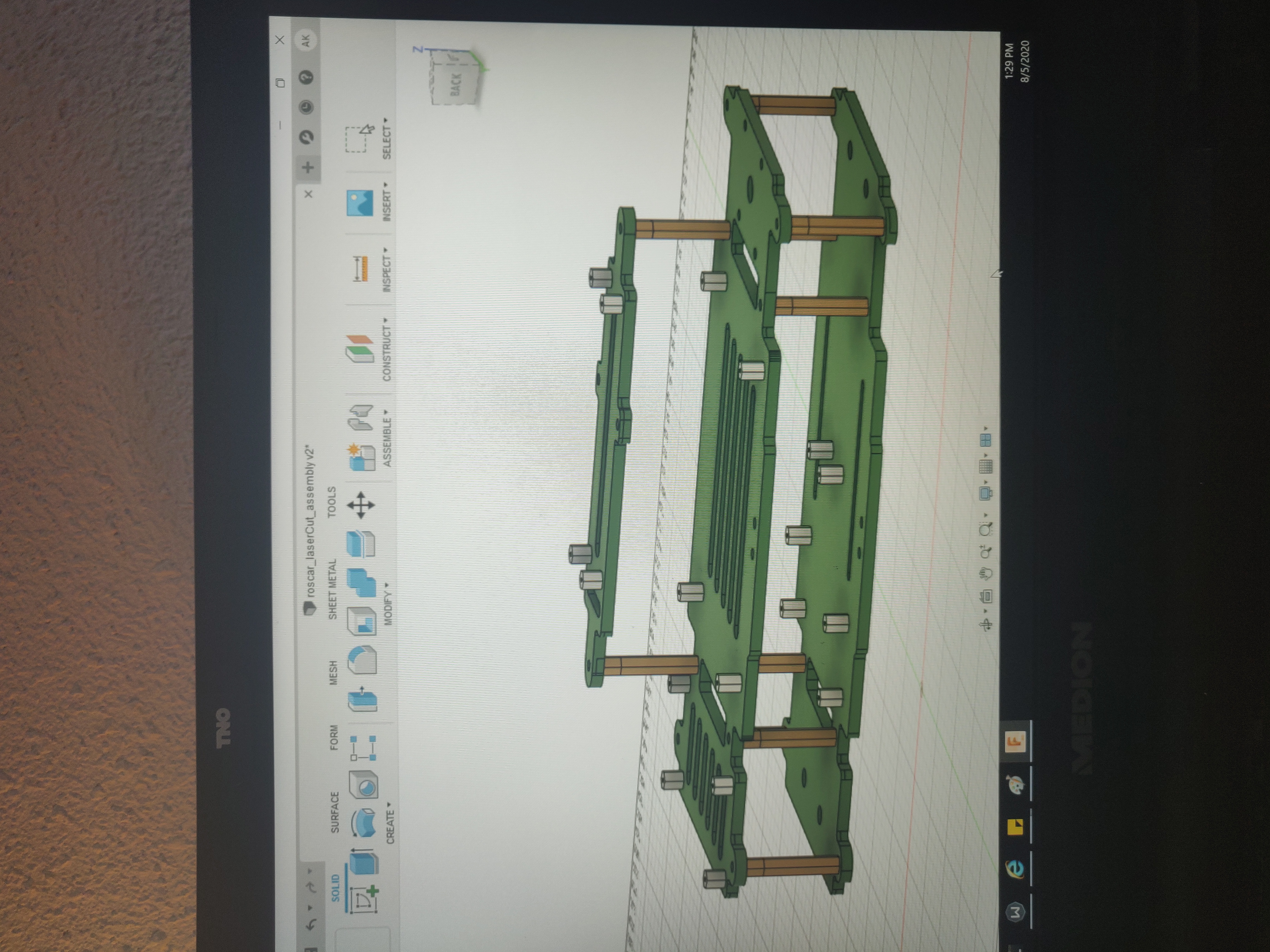

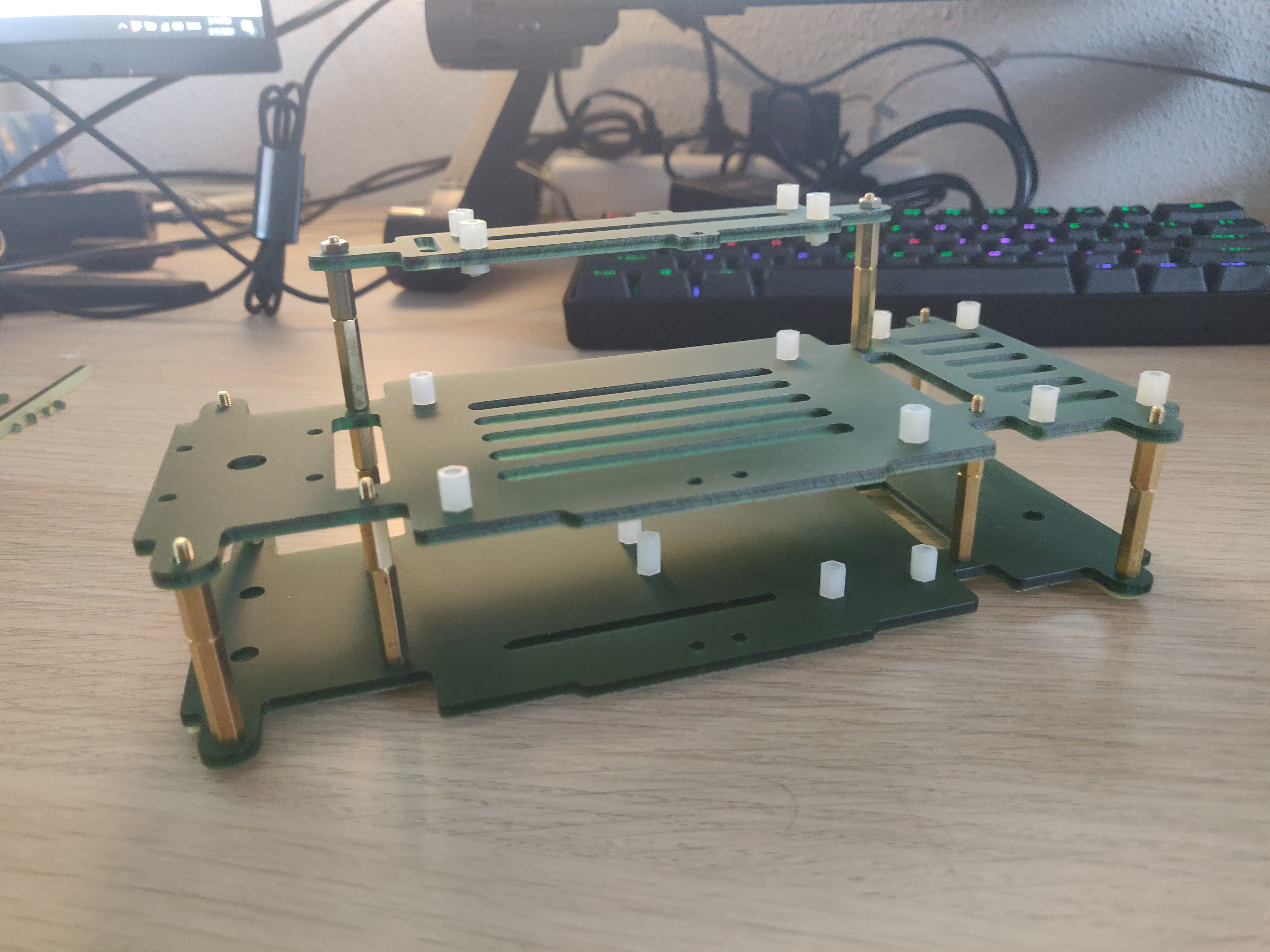

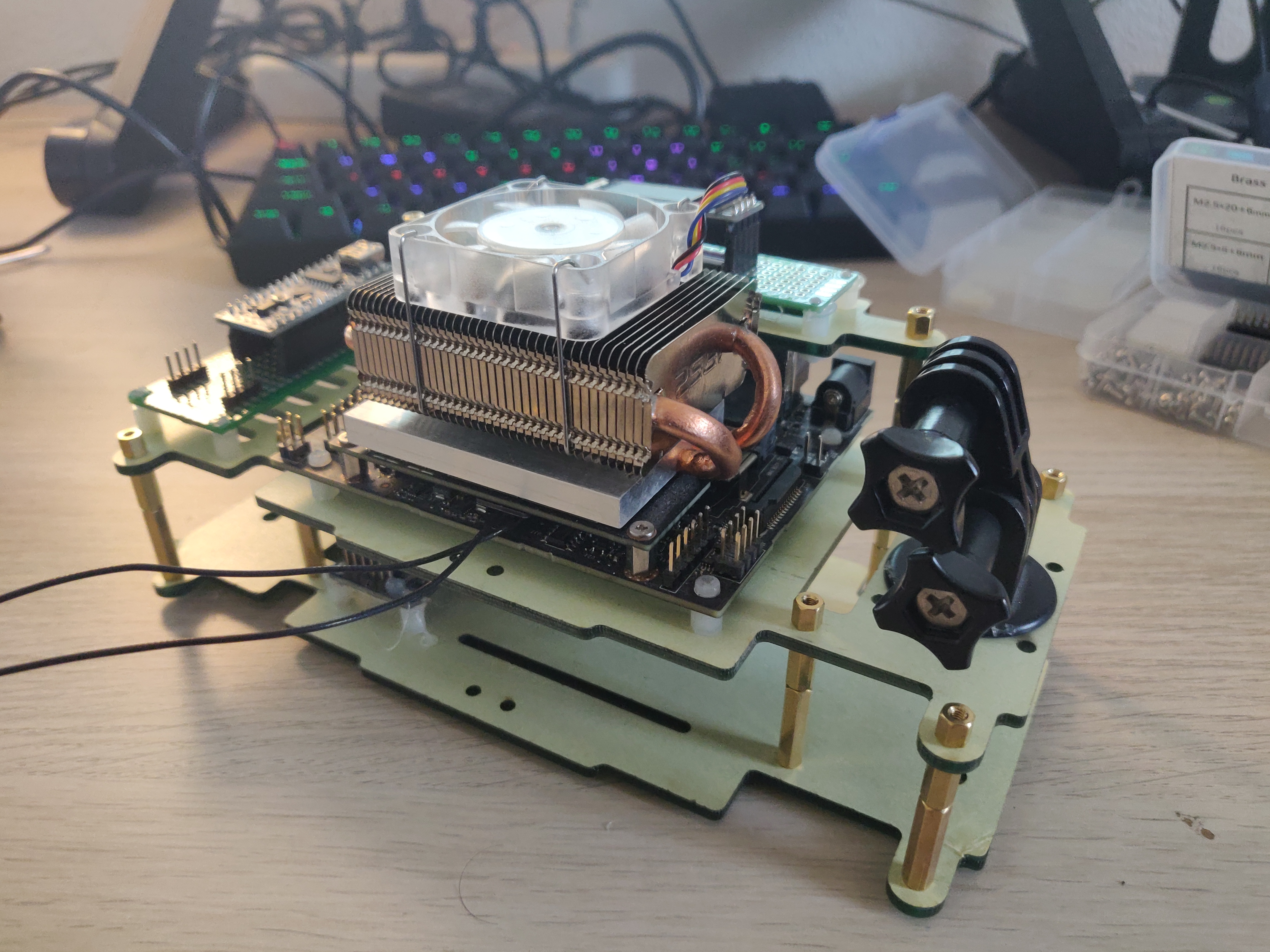

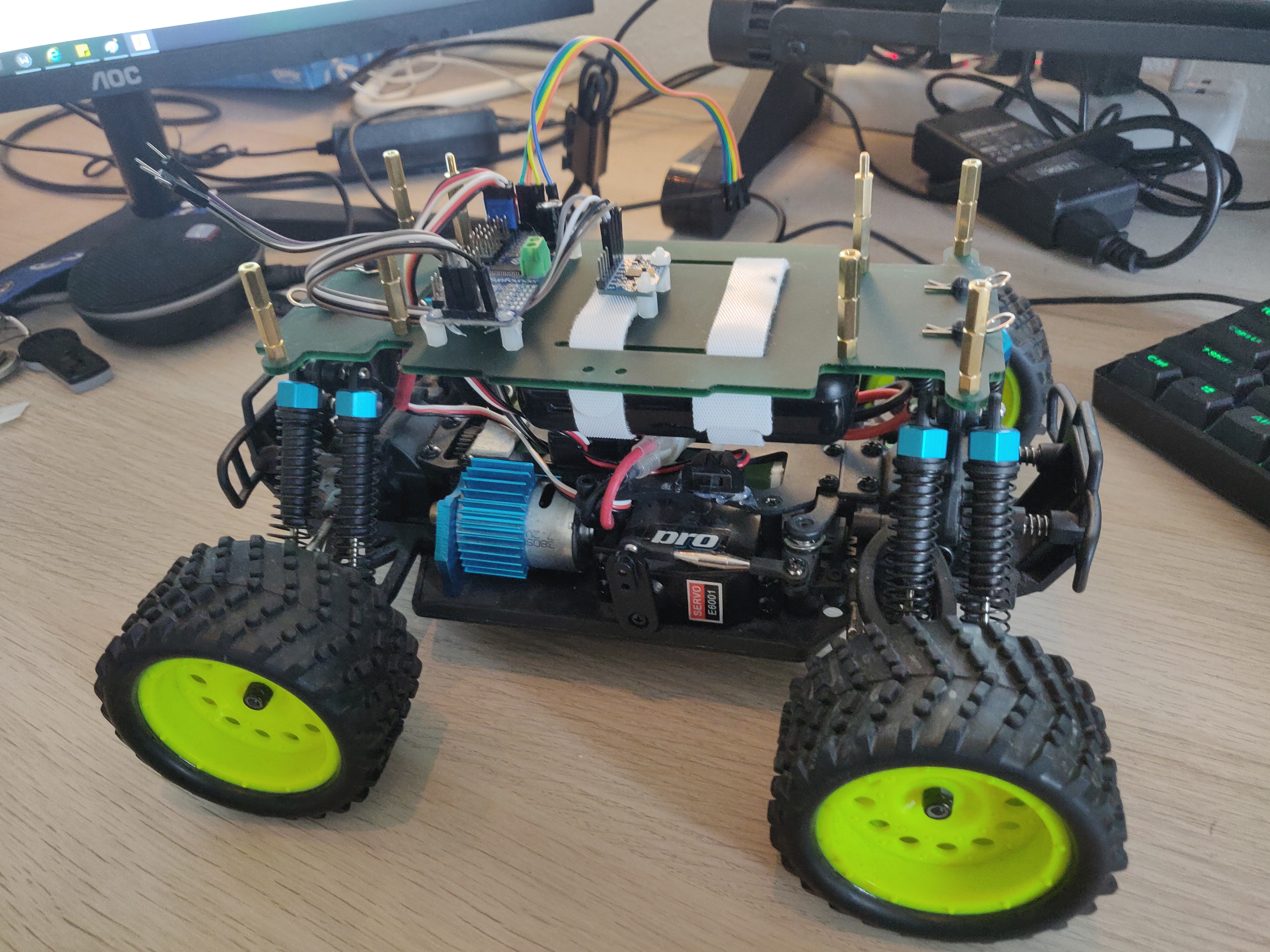

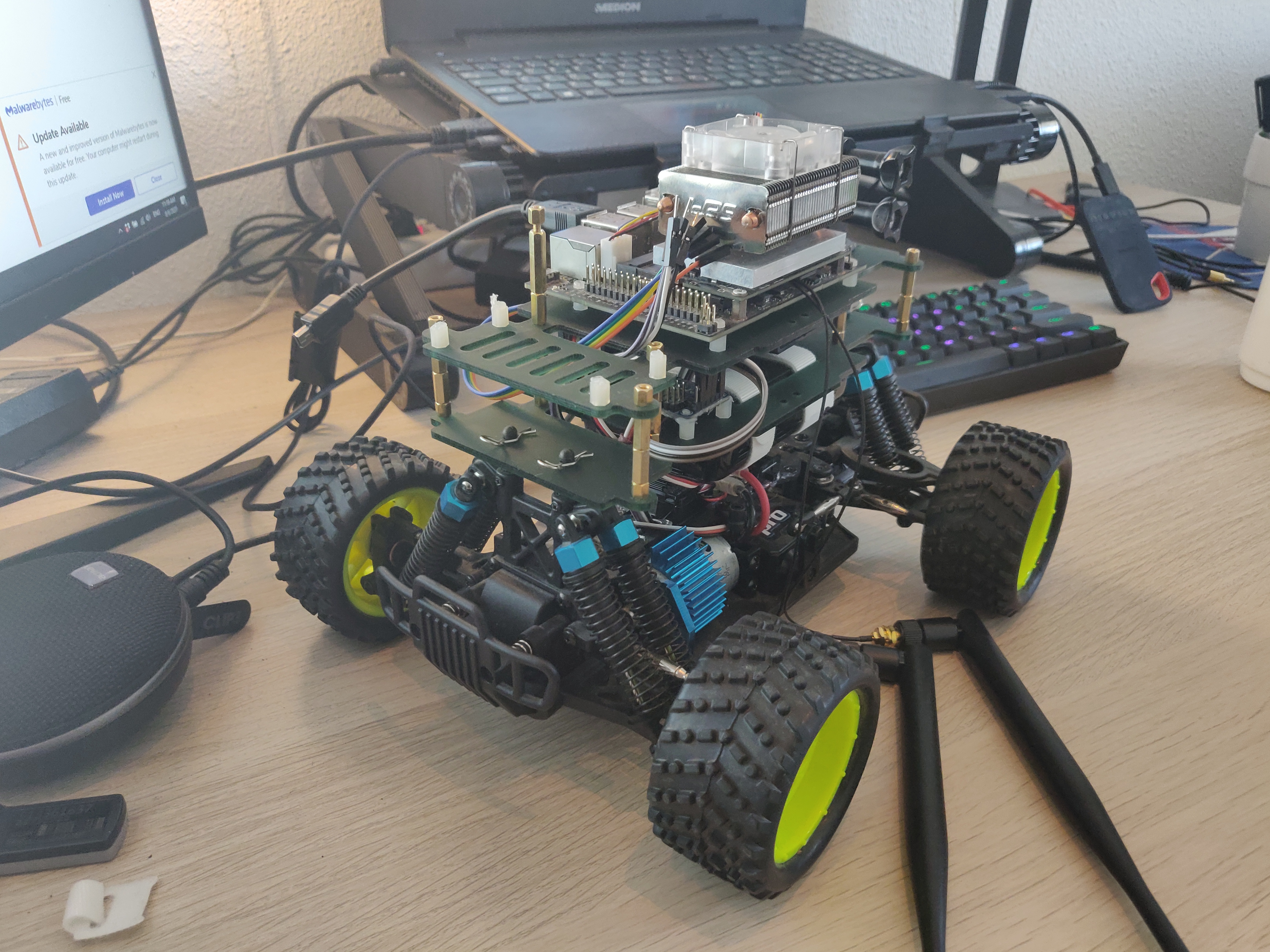

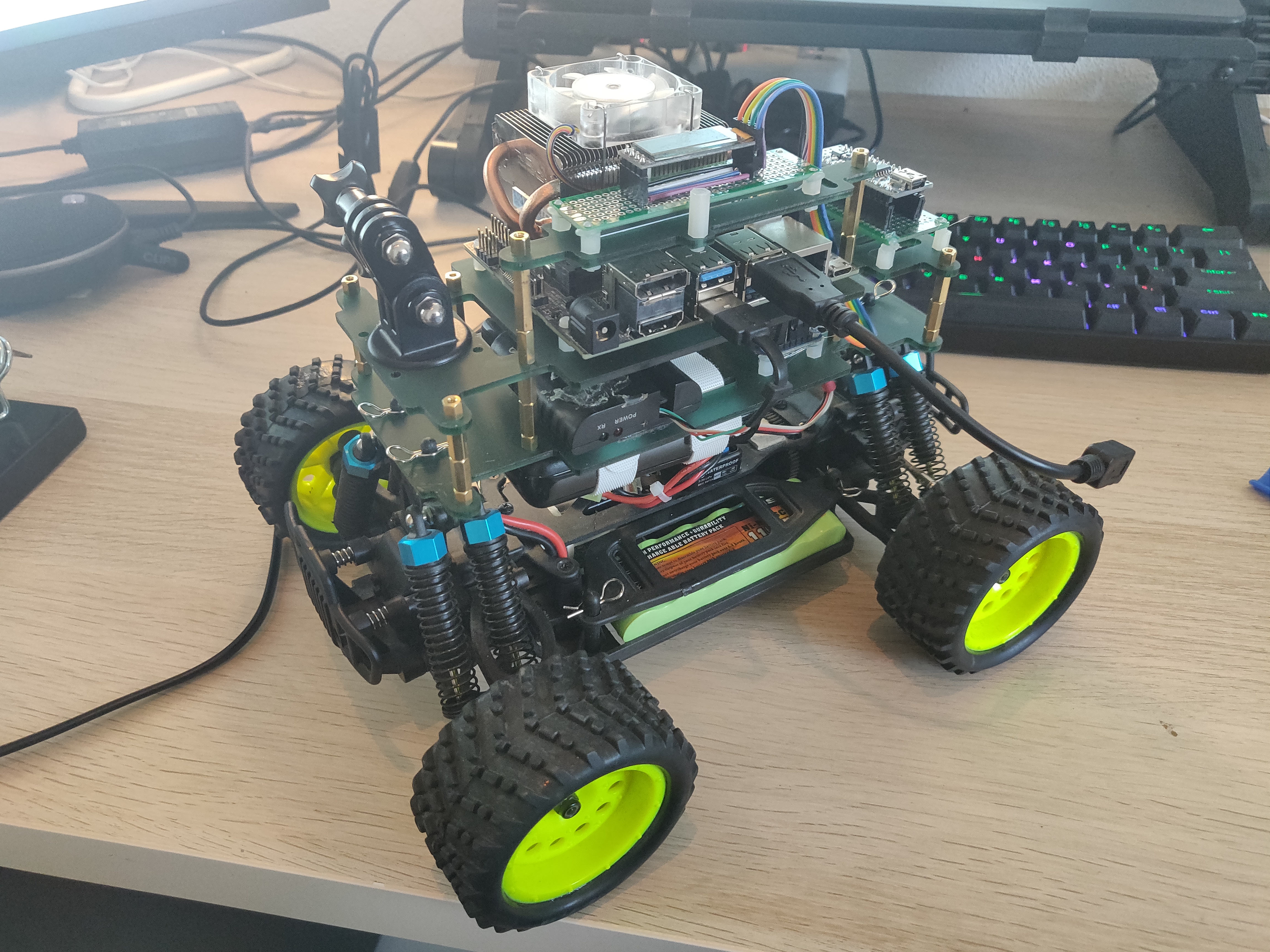

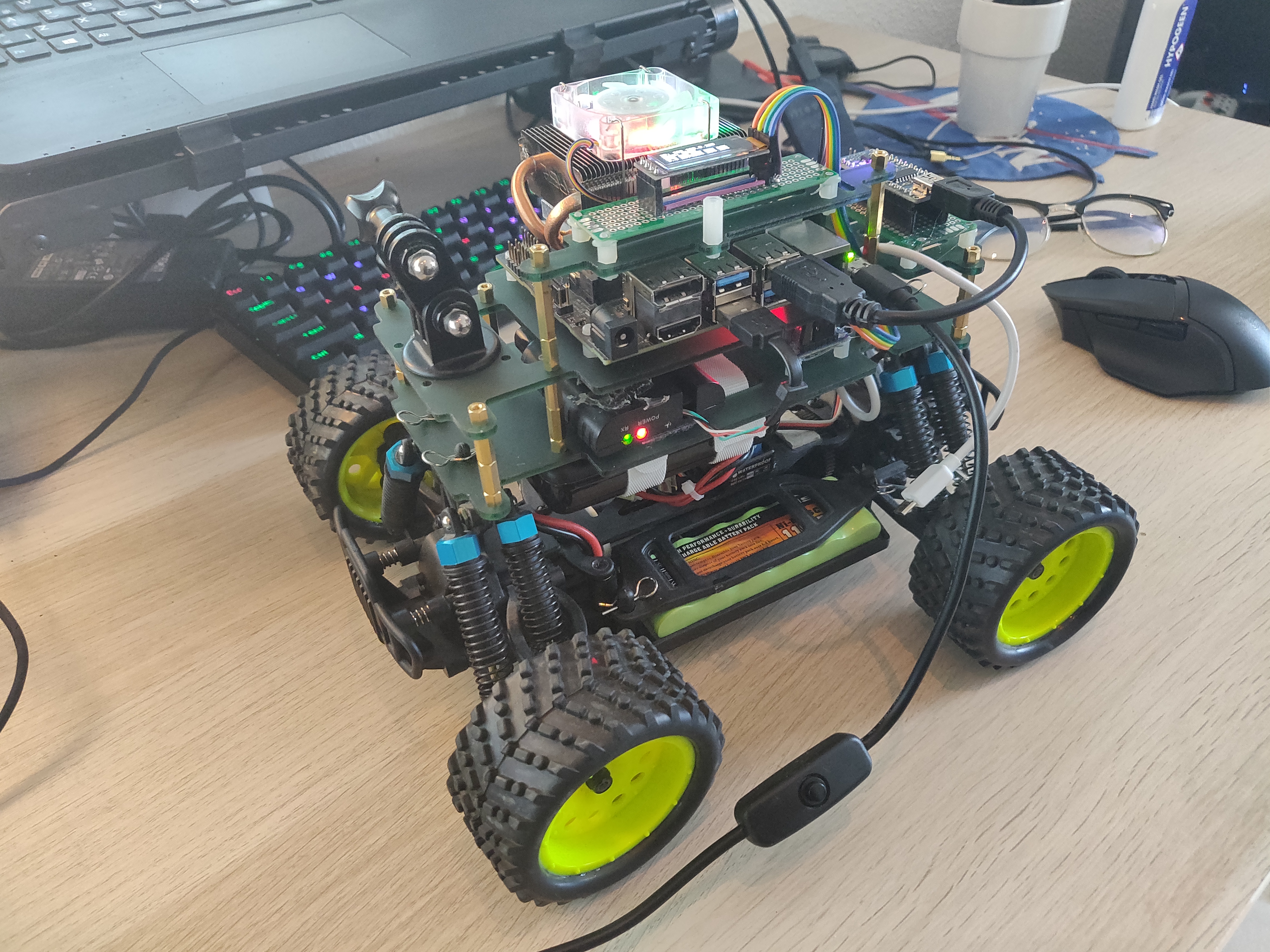

The design is three-tiered as in the image below. On the bottom most tier, the I2C servo board, the IMU and the battery pack are attached with nylon standoffs and zip ties. On the layer above it, the Jetson Nano and the Arduino Nano are attached. The camera is also to be mounted on this tier, but for now I have a GoPro mount as a placeholder. The topmost tier holds a small prototype board with the PiOLED display, connected to the Jetson Nano via I2C.

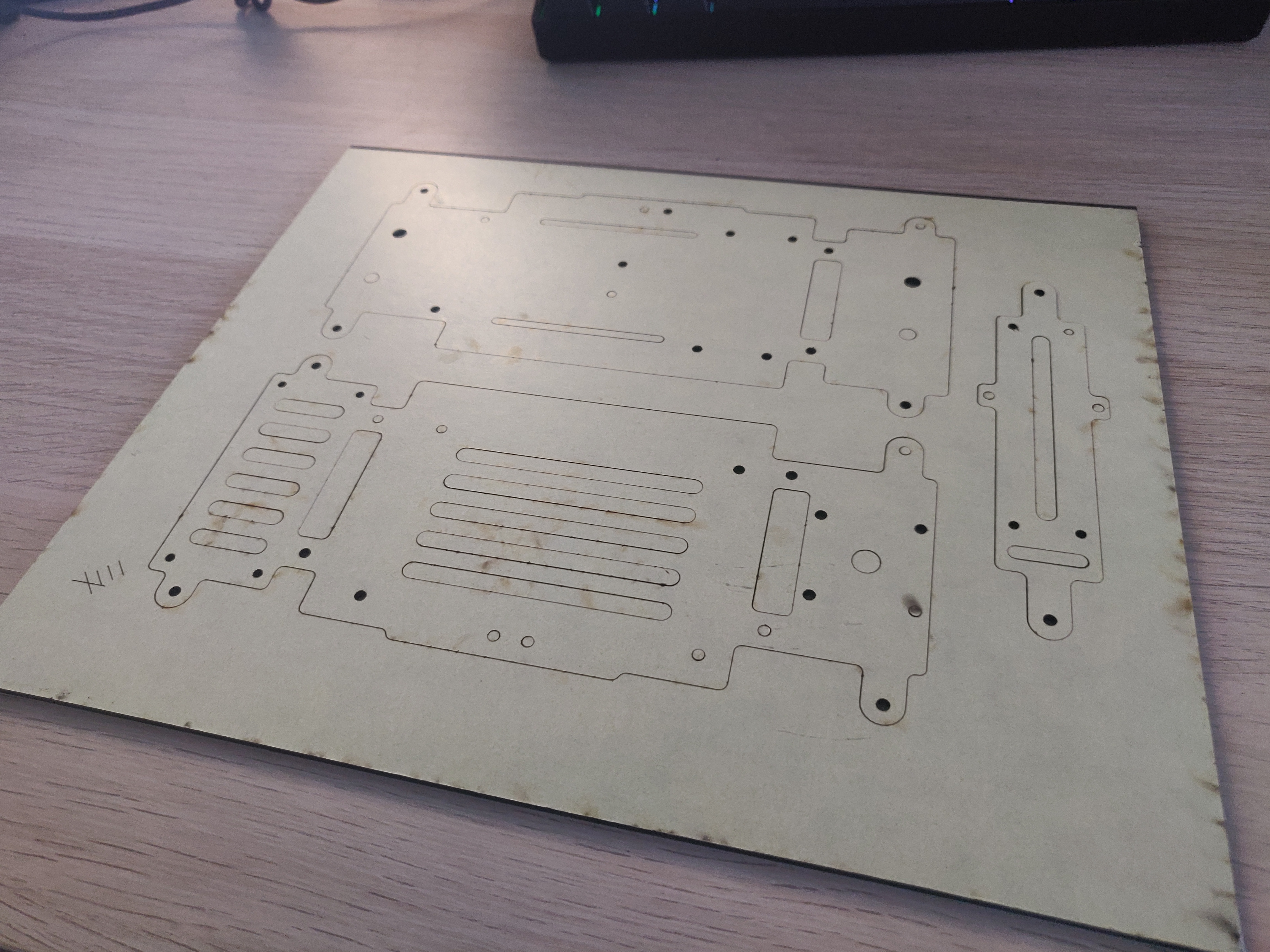

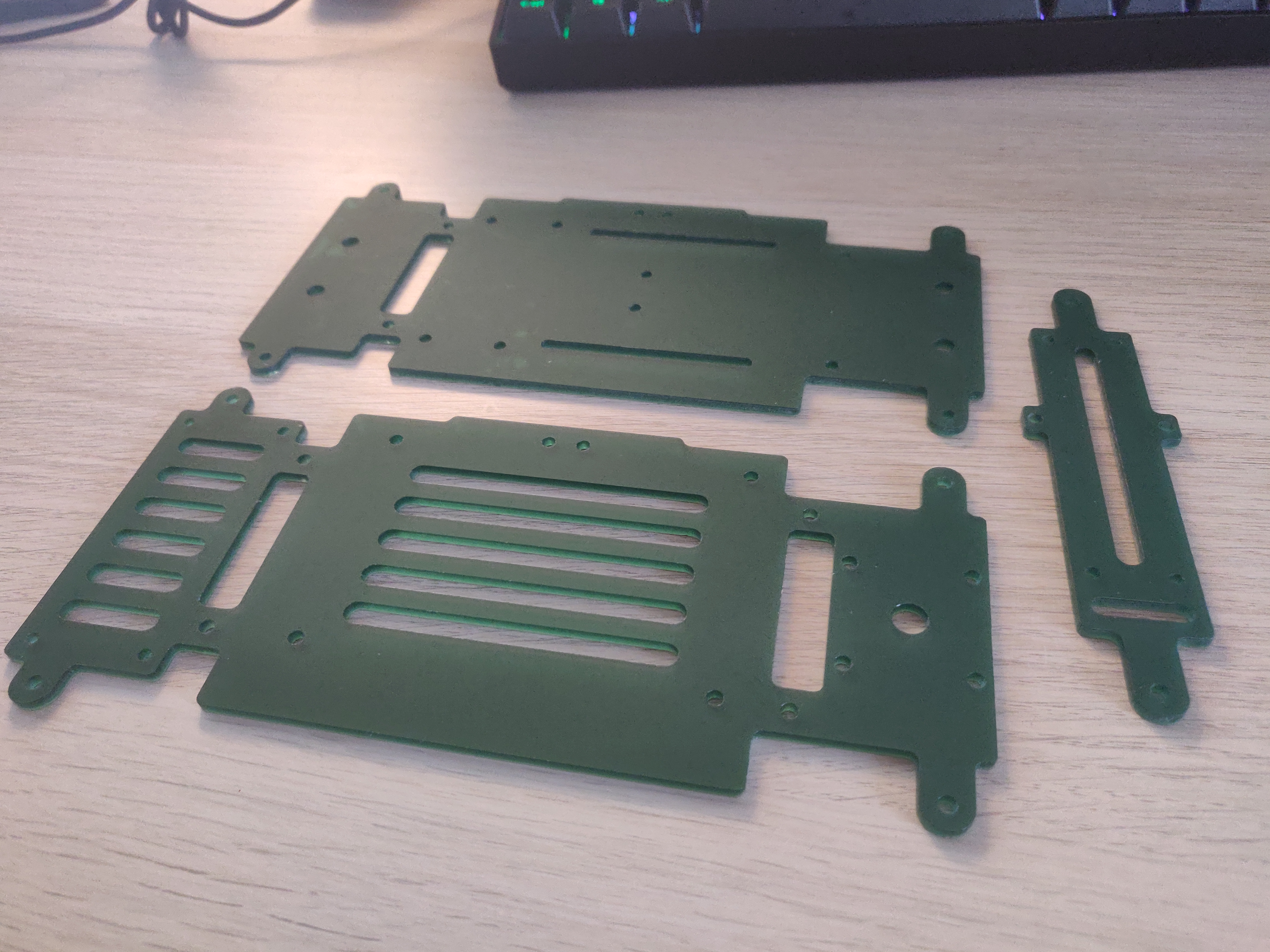

I had originally planned on using the laser cutter at work, but due to the Covid-19 pandemic, this was not possible. This is where I found Snijlab.nl. Within minutes, I was able to upload my design file, choose my material, and pay for the order and shipping. I placed the order on the weekend and I received the parts by Wednesday!

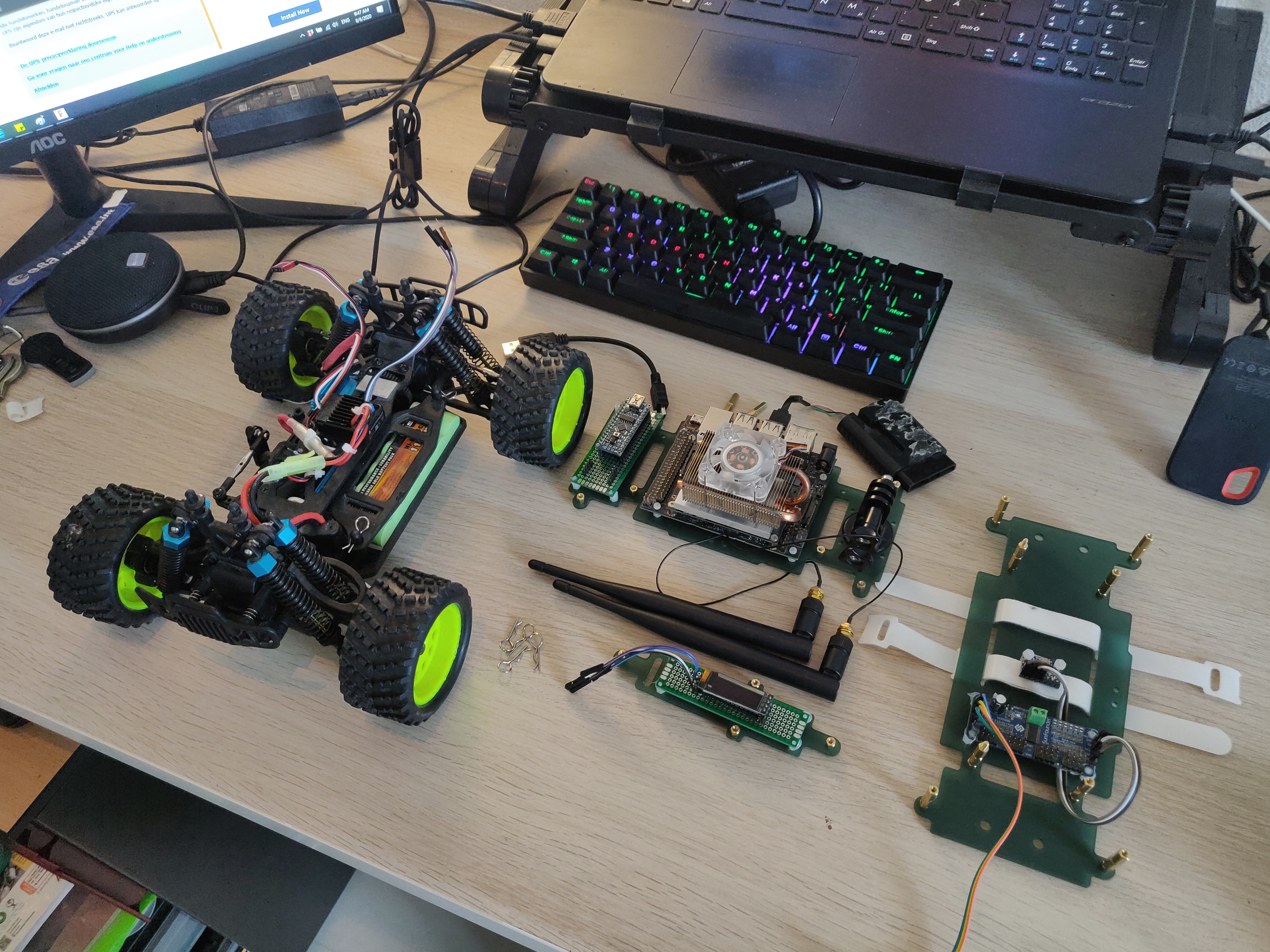

While I was satisfied with the parts, the fact that I had that tape was still bugging me. So, with the scrap acrylic parts, I decided to try and remove the adhesive tape. It took some agressive scratching with a screwdriver but I was finally able to remove most of the adhesive. So, I disassembled the car and removed the adhesive tape. It took a while but it worked. I clicked a new set of pictures to show the different steps of assembly.

Finally, I have 3 hardware updates still to make. Firstly, I need to design and print a mount for the WiFi antenna. Next, I need to add a prototype board with a LED/push-button interface for better control, and then design and print a mount for it. I also need to design and print a GoPro compatible mount for the camera. Finally, once I get started with the ML part, I will have an idea of the perfect orientation of the camera. I can then design and print a fixed camera mount instead of the GoPro links.

The next blog post is probably going to be in a few months from now. I plan on taking it easy and getting some outdoors time on the weekends, since the weather is so nice.